Description

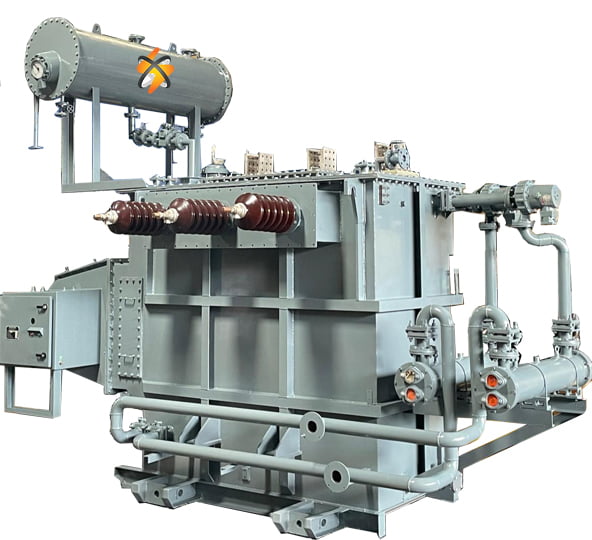

A furnace transformer is a specific type of transformer designed for use in industrial applications, particularly in electric arc furnaces (EAFs) used for steel making.

Furnace transformers are designed to supply high currents at low voltages, typically ranging from a few hundred volts to a few thousand volts, to power electric arc furnaces used in steel production. These transformers step down the high-voltage electricity from the power grid to the lower voltages required for the operation of the furnace.

RANGE:

- 1000 Hz| up-to 30Mva

- Voltage class: 433v, 3.3kv, 6.6kv, 11kv, 22kv, 33kv, ++

- Low voltage: 400v, 440v, 500v, 575v, 750v, 800v, 1000v, ++

- Tap changer: OLTC, OLTC

- Cooling: ONAN,OFWF, ONAF, OFAF,ONWF

USE CASE:

Chemical and Metallurgical Industries: Furnace transformers may find applications in chemical and metallurgical industries where high-temperature reactions are involved in the production of various chemicals, alloys, and materials. These industries often require specialized equipment such as electric arc furnaces for carrying out their manufacturing processes.

Steel plant: Electric arc furnaces (EAFs) are a crucial component in modern steel production processes. Furnace transformers are essential for providing the high currents needed to generate the intense heat required to melt scrap steel and other raw materials in the EAF.

Metal smelting: In addition to steel making, furnace transformers can also be used in other metal smelting processes where electric arc furnaces are employed. These processes may involve the smelting of non-ferrous metals such as copper, aluminum, and zinc, as well as the recycling of metal scrap to produce secondary raw materials.

They play a critical role in providing the high currents required for melting metals and facilitating various manufacturing operations in industries such as steel production, foundries, metalworking, and chemical processing.